The Aoweier Cleaning car wash machine is used for high-pressure washing and brushing of different types of boxy vehicles like large buses, double-decker buses, city buses, and minibuses. It uses an advanced touch screen control system, which displays information in both Chinese and English. The language can be customized according to customer needs. The machine allows easy interaction with automatic and manual control options.

The computer system automatically adjusts the brush distance based on the vehicle’s size (length, width, and height), ensuring effective cleaning without scratching the vehicle. It provides thorough cleaning without missing any spots. The machine also features automatic fault detection and alarms, a system for recognizing the vehicle’s shape, a display for troubleshooting methods, a car wash counting system, and an automatic drainage function in winter to prevent freezing.

The design includes multiple safety protections, making the machine highly reliable and automated. It uses high-quality electronic components from well-known international brands, which are stable and have a low failure rate. The machine is designed to work safely for a long time and meets international standards.

How the Car Wash Machine Works

- Parking: The driver parks the vehicle in the designated washing spot.

- Washing Process: The process starts with the machine detecting the vehicle’s position, then proceeds with high-pressure water and foam cleaning, followed by large brushes on both sides, and finishes with another high-pressure water rinse for a complete cleaning.

- Water Recycling: The machine has a wastewater reuse system that can handle over 5 tons of water, making it energy-efficient.

- Cleaning Methods: The machine uses brushes (made of non-porous foam), cleaning agents, and high-pressure water for thorough cleaning.

- Safety Features: It includes an automatic sprinkler system, current control, fault detection and alarms, an emergency stop, and winter antifreeze features.

- Main Features: The machine is computer-controlled, highly automated, easy to operate, energy-efficient, environmentally friendly, and has a long service life. It is cost-effective with low maintenance and good anti-rust performance.

When the vehicle enters the car wash machine, it can be started with a remote control button. The two large side brushes clean both sides of the vehicle using sensors, while the top brush adjusts automatically. The fully automated system works continuously without pauses, saving time and improving cleaning efficiency. This makes it an ideal choice for modern car wash facilities.

Technical Parameter

| Machine size机器尺寸(L*W*H)mm | 3000(L)*4600(W)*5500(H) |

| Installation Dimension安装尺寸(L*W*H) | 20000*6000*6000mm (L*W*H) |

| Washing Car Size洗车尺寸(mm) | 13000(L)*2700(W)*4500(H) |

| Structure and Material结构材质 | 镀锌管(颜色可选)/Galvanized pipe (color optional) |

| Motor waterproof level防水级别 | IP68 |

| voltage/ power电压/负荷 | 3-380 V, 50 HZ, 10 KW, |

| Water consumption用水量 | 约150-200L/辆,About 150-200L/ vehicles, |

| Car washing speed清洗速度 | 15-20pcs/ hr |

| Control panel屏幕 | 按键+7“真彩色电子触摸屏+遥控器/Button +7 “true color electronic touch screen + remote control device |

| Brushs刷数量 | / Top brush group 1 (Frequency conversion automatic adjustment up and down)Two sets of vertical brush (auto adjust the vehicle profile) ,顶刷1组(电流感应自动调节),立刷2组(自动调整清洗宽度尺寸) |

Function

| LOGO定制/Custom logo | √ | 灯光提示Light navigation | √ |

| 故障报警/Fault alarm | √ | 智能仿形电流顶刷系统/Intelligent profiling current top brush system | √ |

| 遥控启动/Remote control | √ | 防碰撞系统/Anti-collision connectionsystem | √ |

| 洗车液系统Foam spraying system | √ | 特殊加厚轴承和精密传动链/Specially thickened bearing and precision transmission chain | √ |

| 电气系统部件采用国际知名品牌/The electrical system components adopt internationally renowned brands | √ | 光电检测系统/Photoelectric detection system | √ |

| 高质量的柔性电线/High quality anti flexible pipes, wires | √ | 防水减速电机/ waterproof reducing motor | √ |

Working Rules

The reciprocating bus washing machine is designed to clean the outside of buses. It includes several main parts: a gantry structure, top brush, large vertical brushes, a walking system, an electric control system, and a mobile cable trough conveyor arm.

Main Parts:

- Gantry Structure:

- The frame of the machine is made from hot-dip galvanized pipes.

- Each part is precisely cut with a laser and then assembled like a puzzle using interlocking joints.

- Top Brush Component:

- This includes one top brush that can move up and down.

- It has a rotating part and a lifting part.

- The lifting motor moves the brush up and down using wheels connected with nylon belts.

- Large Vertical Brush Components:

- There are two large vertical brushes.

- They can move left and right thanks to a rotating device and a motor.

- The brushes extend and retract based on the resistance between the brush and the bus surface.

- Walking System:

- This is installed on the bases at both sides of the machine.

- It uses a reduction gear system to move the machine along a guide rail by turning a chain and wheels.

- Electric Control System:

- This system is housed in an electrical control cabinet.

- It allows for automatic control of the car wash through a computer touch screen.

- The control system uses a programmable controller with sensors to manage the top brush, large vertical brushes, and the machine’s movement.

- Mobile Cable Trough Conveyor Arm:

- This part protects the water, electrical, and air lines.

- It is stretchable, insulated, and wear-resistant to ensure durability.

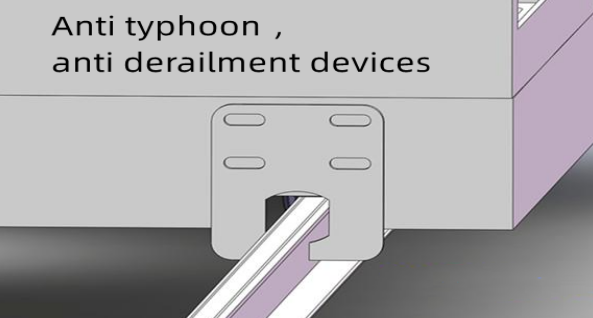

Safety anti derailment device and safety protection device

A special safety buckle has been designed to prevent the bus washing equipment from derailing. It takes into account the height, width, and outdoor conditions that can affect the washing process. This design reduces wear and tear, extends the life of the pulleys, and eliminates safety risks.

Introduction to the brush brushing function

Performance Description:

- High-Tech Solid Foam:

- Made in China with Italian quality.

- It doesn’t absorb water or pick up dirt.

- Non-Static 3D Cleaning:

- Cleans the surface of the vehicle without scratching the paint.

- Long-Lasting:

- It has a very long service life.

- It is economical, environmentally friendly, and practical.

- EVA Foam Brush:

- This is a third-generation car wash brush.

- The bristles are soft and don’t absorb water.

- They don’t pick up sand or debris, have a long life, and don’t damage the car.

- It’s widely used.